Innovation in the plastics industry:

how graphene masterbatches are changing the game

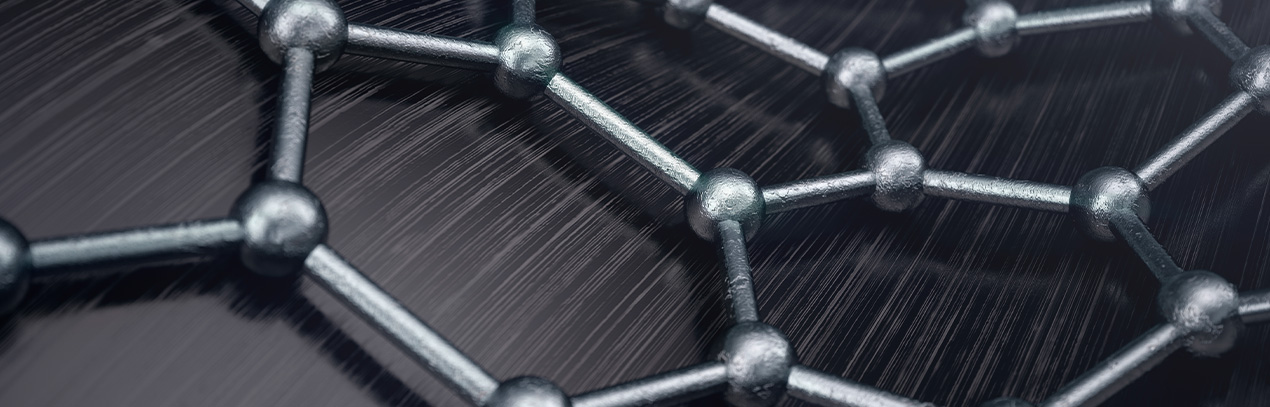

Graphene has extraordinary electrical, optical, thermal properties and high mechanical resistance. The properties of graphene are attributed to its structure in the form of two-dimensional (2D) sheets, formed by hexagonal bonded carbon atoms and a thickness of one carbon atom.

Today, graphene is the most promising nanotechnological additive in the plastics industry. The incorporation of graphene and its derivatives (graphene oxide, GO) in different polymer matrices (masterbatches), have great potential for a wide range of applications. The graphene masterbatch can act as a mechanical reinforcement or conductive additive for both thermoplastic and thermosetting materials. They can be used in the automotive, aerospace, electronics or packaging sectors.

Graphene-based polymeric compounds have shown significant improvements in properties such as elastic modulus, tensile strength, impact resistance, electrical conductivity, resistance to UV radiation, thermal stability, antimicrobial property, impermeability or barrier effect (it does not allow the diffusion of moisture or other molecules).

Currently Energeia – Graphenemex®, a leading Mexican company in Latin America in research and production of graphene materials for the development of applications at an industrial level, through its Graphenergy Masterbatch line, has developed and sells a wide range of masterbatches with graphene, based on various polymers, such as PP, HDPE, LDPE, PET and PA6.

Our Masterbatches are granular materials that act as multifunctional additives. The incorporation of graphene in different polymer matrices has shown important effects on the properties and processing conditions of plastics, among which are:

- Increased resistance to tension, deformation and impact

- Increased resistance to ultraviolet rays

- Excellent dispersion

- Improves processing conditions (thermal stability)

- Acts as a nucleating agent (modification of the crystallization temperature of the polymer)

In this sense, it has been found that the incorporation of graphene and its derivatives, as well as the concentration, can modify the physicomechanical properties of the polymer to be processed. The addition of masterbatch to different polymers has improved the final characteristics of the material to a lesser or greater extent, for example:

- Additivation of Polypropylene (PP) with polypropylene-graphene masterbatch (MB-PP/GO), increases tensile strength (8%) and rupture percentage (29%).

- Additivation of Polyethylene (PE) with polyethylene-graphene masterbatch (MB-PE/GO), improves tensile strength (17%), flexural strength and rupture strength (66%).

- Additivation of Polyethylene terephthalate (PET) with polyethylene terephthalate-graphene masterbatch (MB-PET/GO), improves resistance to humidity, increases tensile strength (72.2%) and improves impact resistance.

- Additivation of Polycarbonate (PC) with polycarbonate-graphene masterbatch (MB-PC/GO), improves resistance to humidity and improves resistance to rupture (276%).

On the other hand, graphene masterbatches can also be incorporated into recycled polymers. Currently, the reuse and recycling of plastic materials are of vital importance in the transition path towards a circular economy. In this regard, the constant washing, pelletizing and reprocessing can cause the loss of physicomechanical properties of recycled plastics, therefore, by adding graphene, these properties can be restored or improved. In agricultural applications, mulch films with increased resistance to ultraviolet radiation can be produced.

References

- Fang, M., et al., Covalent polymer functionalization of graphene nanosheets and mechanical properties of composites. Journal of Materials Chemistry. 19(38): p. 7098-7105.

- Kim, H., A.A. Abdala, and C.W. Macosko, Graphene/Polymer Nanocomposites. Macromolecules. 43(16): p. 6515-6530.

- Balandin, A.A., et al., Superior Thermal Conductivity of Sin gle-Layer Graphene. Nano Letters, 8(3): p. 902-907.

- Nabira Fatima, Umair Yaqub Qazi, Asim Mansha., Recent developments for antimicrobial applications of graphene-based polymeric composites: A review, https://doi.org/10.1016/j.jiec.2021.04.050