Innovation in Non-Stick Coatings:

Integration of Graphene Materials for Enhanced Properties and Performance

Currently, non-stick coatings refer to coatings that, to some extent, prevent the adhesion of substances, whether solid or liquid, to the surface they are applied on. The non-stick capability of these coatings is based on their very low surface tension, also known as surface energy, represented by “γ”.

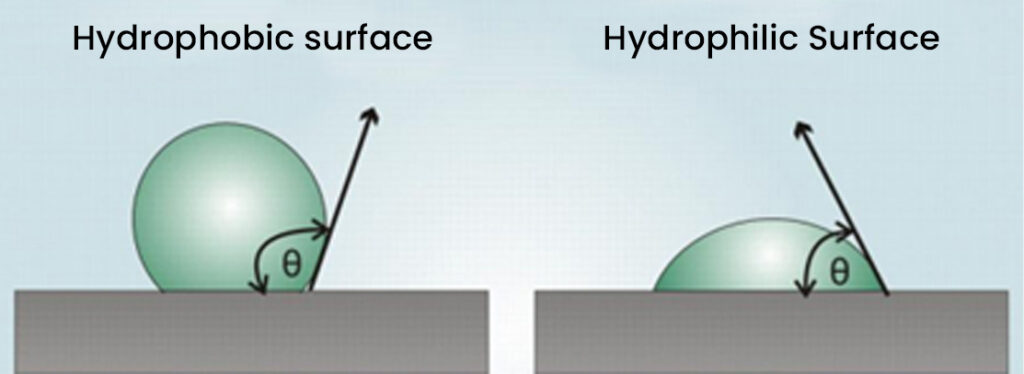

For coatings to be considered non-stick, they must have a surface energy, γ, less than 26 mJ/m² and water contact angles greater than 90°. A surface where the drop forms a contact angle greater than 90° is a hydrophobic surface. This condition implies low wettability, adhesiveness, and surface energy (see Fig. 1). In contrast, if the surface is hydrophilic, a contact angle less than 90° will be observed, and the wettability, adhesiveness, and surface energy will be high.

Industrially, there are multiple non-stick coatings based on fluoropolymers. The uses and applications of fluoropolymers in coatings cover a wide range of products. The non-stick effect and easy demolding allow their use in various industries, such as textile, chemical, automotive, and food industries, for the production of utensils, molds, tools, and equipment that need to be isolated from chemicals or food.

Most non-stick coatings have high thermal resistance; however, they do not have great abrasion resistance. The use of fluoropolymers in kitchen utensils raises concerns about the potential health risks, as harmful substances might be released during use.

In recent years, Energeia – Graphenemex®, a Mexican company leading in graphene material production, has implemented the use of these carbon-based nanomaterials. Graphene materials, such as graphene oxide and graphene, enhance properties in coatings, for example, anticorrosive, antibacterial, greater abrasion resistance, and high UV resistance.

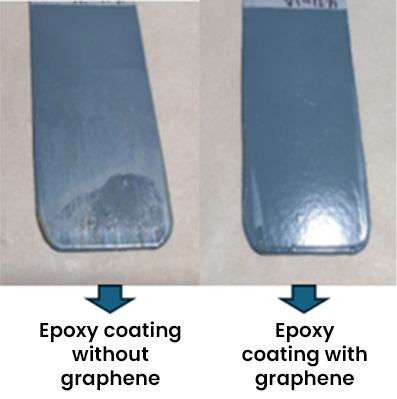

During these property evaluations, it was observed that graphene materials can also be used as new additives for developing non-stick coatings. Incorporating graphene materials into epoxy-type coatings improved substrate adhesion; however, the finish of these coatings was smoother and shinier. When exposed to a corrosive environment, the coating showed hydrophobic behavior, keeping its surface cleaner compared to the control coating (without graphene material), which gradually lost its shine and showed wettability and contaminant deposition on the coating surface (see Fig. 2).

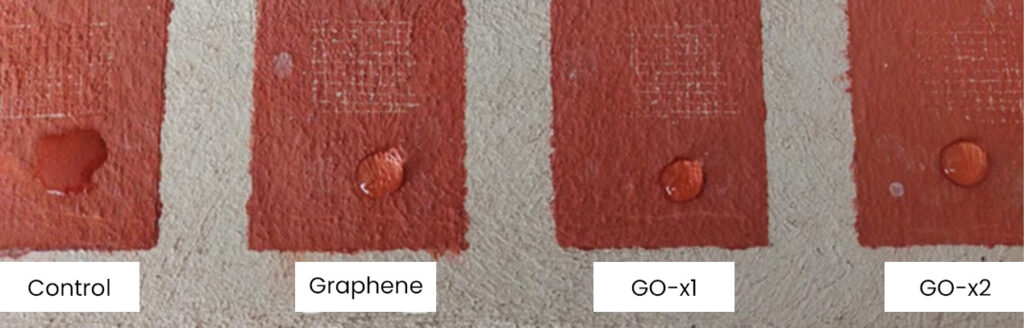

Furthermore, the non-stick effect of an ecological coating with and without graphene material was evaluated. This coating is made of lime, nopal mucilage, and mineral pigments. It is well known that lime and carbonate-based materials absorb moisture easily, so the effect of graphene material in lime-based paint was studied. The results showed that the paint had an antimicrobial effect, greater UV resistance, and higher impermeability (non-stick effect).

In Fig. 3, the response of a lime-based coating with and without graphene material, when wetted by water, is shown. The coatings with graphene materials (Graphene and graphene oxide (GO)) at different concentrations showed very little deformation in the drop as its internal energy was higher than the surface energy, displaying hydrophobic behavior (water repellency). In the case of the control coating (without graphene material), it was observed to have very little non-stick capacity, absorbing water more easily due to high surface energy. The drop spread on the surface immediately when the water drop fell on the surface, showing highly hydrophilic behavior. These results showed that graphene materials modified the nature of the coating, i.e., they modified the surface energy of the coatings at the surface level.

Currently, Energeia – Graphenemex®, a leading Mexican company in Latin America in the research and production of graphene materials for industrial application development, offers various types of graphene materials for use in developing and producing anticorrosive, antibacterial, and enhanced non-stick coatings.

References

- Tong, Yao &Song, Mo. (2013). Graphene based materials and their composites as coatings.

- Zhen, Z. & Zhu, H. Graphene: Fabrication, Characterizations, Properties and Applications. Graphene (Academic Press, 2018).

- Sachin Sharma Ashok Kumar, Shahid Bashir, K. Ramesh, S. Ramesh, Progress in Organic Coatings, 154, (2021)