Nanotechnology and tube labelling:

an effective solution for material identification

Mexico City – Energeia Graphenemex® is a pioneering nanotechnology company in Latin America, dedicated to the research and production of graphene materials, as well as the development of applications at an industrial level.

Within the company’s research and development protocols, it seeks to solve problems faced by companies or industries on a daily basis, for which research agreements or alliances are made to seek to develop a solution in which graphene is become the agent of change.

Why we developed Graphenergy Ink?

In 2019 there was an approach with one of the largest companies in the world in the manufacture of steel tubes that was facing a serious problem in its process of marking the tubes, which were marketed.

During the tube manufacturing process, marking is necessary for rapid identification and traceability, optimizing all the processes and procedures that each of the steel tubes must go through. However, there was a problem: the ink used in the marking process erased very easily and did not withstand application temperatures above 70°C, in addition to having low resistance to abrasion.

In the course of manufacturing steel tubes, it is normal for these tubes to be subjected to different processes; rotation on conveyors, rollers, shot blasting and transport with cranes, where there is high friction and abrasion between tubes, so the ink ended up being torn off, erasing the marking on the metal surface, and thus losing all control and traceability of the tubes.< /p>

To offer a comprehensive solution to the marking problem, Energeia Graphenemex®, through its Graphenergy Anticorrosive line, developed a new white marking ink with graphene oxide.

Among the most important characteristics of this developed graphene oxide marking ink are:

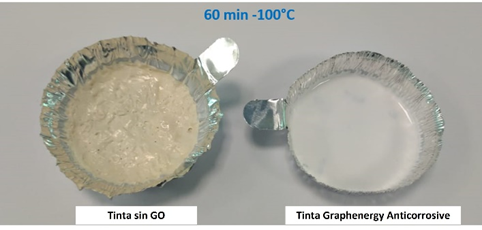

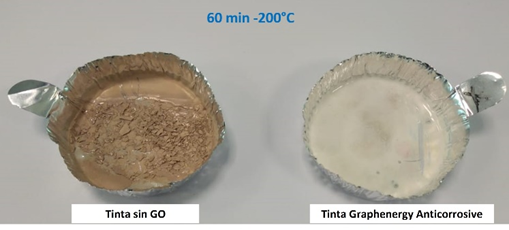

- Extraordinary thermal resistance (resists more than 200 °C)

- Resistance to UV rays

- Anticorrosive property

- High adhesion to metallic substrates

- Abrasion resistance

- Ultra-fast drying (3 seconds)

- Excellent covering power

Thermal resistance to extreme temperatures

Thanks to the development of the marking ink, the problem of the lack of adherence of the marking ink was solved, as well as the issue of abrasion that occurs when moving the tubes during transport, thus maintaining the traceability of the tubes .

Due to its characteristics, the production process was additionally benefited by:

- Ultra-fast drying: it allowed the production line not to stop, which could improve production times

- Anti-corrosion protection: a version of the transparent ink was formulated that is applied on the tubes after marking, preventing them from rusting.