Textile Innovations:

Exploring Graphene Trends in the Industry

Part II

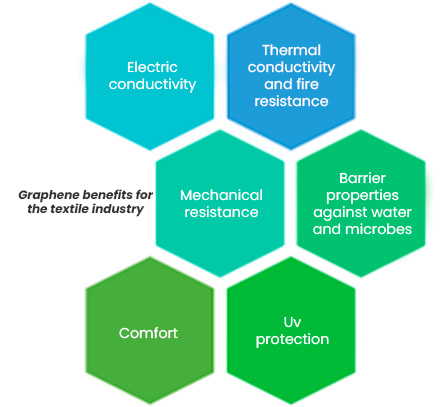

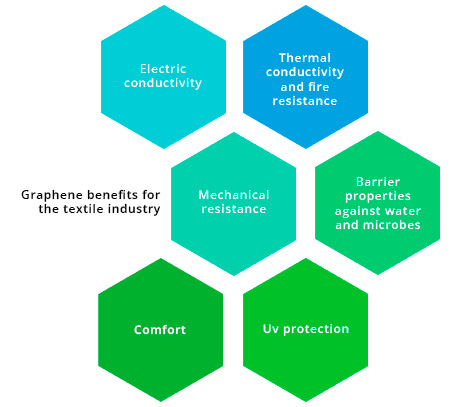

In the previous article on Textile Innovations, we explored the trends of graphene in the industry, focusing on its practical applications in textiles, leveraging its electrical, thermal, fire resistance, and mechanical properties. In this article, we will delve into the advantages of graphene, considering its multifunctional benefits such as its barrier effect with a focus on waterproofing and antimicrobial properties, as well as its contributions to UV protection and comfort.

Mechanical Resistance

The well-known high mechanical strength of graphene, with a Young’s modulus of ~1100 GPa and a tensile strength of 42 N/m, makes a single layer of graphene 200 times stronger than steel of equal thickness. This strength can be utilized in graphene-modified composites, enabling them to withstand significant forces without deformation, achieving greater strength with a smaller gauge. In wool fabrics, excellent linearity with over 20% elongation, moisture resistance from 30 to 90%, and good electrical and mechanical properties have been observed.

Barrier Properties

The hydrophobic nature of graphene, the size of its nanochannels, and the high electron density on its surface make it highly impermeable to particulate matter, liquids, and gases. Graphene compounds interact with other materials and molecularly organize their three-dimensional structure, creating compounds that are not only impermeable but also mechanically stronger and with significant recovery or deformation resistance.

Antimicrobial Barrier

Graphene’s antimicrobial capability is advantageous in the textile industry, considering the persistent challenge of microorganism anchoring, proliferation, and spread on garments, especially in the medical sector.

Antimicrobial Barrier Mechanisms

– Size Exclusion: The interatomic distance of carbon atoms in graphene (0.142 nm – 0.9 nm) provides a barrier that microorganisms, with sizes ranging from 10 nm to 3 micrometers, cannot permeate.

– Oxidative Stress: Interactions between the polar ends of phospholipids in cell membranes and graphene generate irreversible oxidative stress and microbial death. Its strong protein anchoring capability can inhibit the enzymatic capacity of some microorganisms.

– Membrane Damage: The sharp edges of graphene layers physically damage the structure of microorganisms, preventing microbial adhesion to surfaces without adverse effects on the skin.

UV Protection

Graphene’s absorption spectrum covers the entire electromagnetic spectrum, with a peak absorption around 281 nm, allowing it to absorb UV radiation with a wavelength between 100 and 281 nm. For wavelengths longer than 281 nm, graphene’s reflective properties play a crucial role in UV radiation resistance and, consequently, in the increased durability of materials exposed to the elements.

Comfort

Traditional textiles like cotton, linen, or silk are highly hydrophilic but have limited water molecule transport capacity. The hydrophobicity of graphene compounds prevents water transport to the inner layer and simultaneously transports water inversely to its outer surface. Its excellent thermal regulation capability prevents the concentration of heat and moisture, creating an environment inhospitable for the proliferation of microorganisms, thus preventing infections, stains, and unpleasant odors.

At Energeia-Graphenemex®, leaders in Latin America in graphene production and development, we are convinced of the tremendous potential of this material to meet the needs of industrial sectors such as the textile industry. We are committed to addressing the scientific, technical, economic, and ethical needs of each project, serving as a strategic ally for companies seeking to innovate and improve their products and processes through the integration of graphene technologies. We look forward to introducing the first graphene textiles in Mexico soon.

Redaction: EF/DH

References:

- Graphene Modified Multifunctional Personal Protective Clothing. Adv. Mater. Interfaces 2019, 6, 1900622;

- Graphene-based fabrics and their applications: a review. RSC Advances. 2016, 6:68261;

- Fabrication of a graphene coated nonwoven textile for industrial applications. Australian Institute for Innovative Materials – Papers. 2016, 2173;

- New Perspectives on Graphene/ Polymer Fibers and Fabrics for Smart Textiles: The Relevance of the Polymer/Graphene Interphase. Front. Mater. 2018, 5:18;

- Graphene applied textile materials for wearable e-textile. 5 th International Istanbul Textile Congress 2015: Innovative Technologies Inspire to Innovate‖ September 11th -12th 2015 Istanbul, Turkey;

- The Effect of Graphene Oxide on Flame Retardancy of Polypropylene and Polystyrene. Materials Performance and Characterization 2020, 9, 1, 284;

- Engineering Graphene Flakes for Wearable Textile Sensors via Highly Scalable and Ultrafast Yarn Dyeing Technique. ACS Nano 2019, 13, 4, 3847;

- Highly Conductive, Scalable, and Machine Washable Graphene-Based E-Textiles for Multifunctional Wearable Electronic Applications. Adv. Funct. Mater. 2020, 30, 2000293;

- Moisture- Resilient graphene – dyed wool fabric for strain sensing. ACS App. Mater. Interfaces. 2020, 12, 11,13265;

- Creating Smart and Functional Textile Materials with Graphene. Nanomaterials and Nanotechnology Biomedical, Environmental, and Industrial Applications. 2021, Chapter 13.;

- Graphene oxide incorporated waste wool/PAN hybrid fibres. Sci Rep 2021, 11, 12068;

- Moisture-Resilient Graphene-Dyed Wool Fabric for Strain Sensing. ACS Applied Materials & Interfaces 2020, 12, 11, 13265;

- Thermal Degradation and Flame-Retardant Mechanism of the Rigid Polyurethane Foam Including Functionalized Graphene Oxide. Polymers 2019, 11, 78;

- Tuning sound absorbing properties of open cell polyurethane foam by impregnating graphene oxide. App Acoustics. 151, 2019, 10;

- Intumescent flame-retardant polyurethane/reduced graphene oxide composites with improved mechanical, thermal, and barrier properties. Journal of Materials Science. 2014, 49, 243;

- Production and characterization of Graphene Nanoplatelet-based ink for smart textile strain sensors via screen printing technique. Materials & Design. 198, 15 2021, 109306;

- Caracterización de un tejido mezcla poliéster/ algodón aplicando grafeno mediante el proceso de adsorción. Tesis 2020;

- Síntesis y formulación de nuevas espumas de poliuretano flexibles con propiedades mejoradas. Tesis 2018.