Innovation with Graphene

Towards a More Sustainable and Efficient Cement Industry

Part 2

For the cement industry, reducing CO2 emissions is not a new topic. Over the past 30 years, producers have managed to reduce approximately 40% of the fuel needed for the clinkerization process, thus reducing CO2 emissions by the same proportion, given that around 900 g of CO2 are produced per kilogram of cement.

Over ten years ago, a collaboration between the International Energy Agency, the Global Cement and Concrete Association (GCCA), and the Inter-American Cement Federation (FICEM) established the first roadmap for emission reduction. This laid the groundwork for the National Chamber of Cement (CANACEM), FICEM, and companies such as CEMEX, Cruz Azul, Cementos Chihuahua, Cementos Fortaleza, Holcim México, and Cementos Moctezuma to evaluate emissions and determine strategies for low-carbon cement production.

According to the CANACEM roadmap, the main indicators for CO2 reduction are 1) the Clinker/Cement ratio, 2) co-processing, 3) energy efficiency, and 4) exploring new technologies such as CO2 capture, clinker reduction, and cement reinforcement.

In a previous article addressing environmental challenges in the construction industry and the goal of net-zero CO2 emissions by 2050, key opportunities for graphene nanotechnology in sustainable construction were highlighted, including:

- Cement reduction,

- Waste utilization,

- Cost reduction,

- Energy efficiency.

On September 4, the website https://www.graphene-info.com/ published the new edition of the Graphene-enhanced Construction Materials Market Report, which delves deeper into the advantages of using graphene in construction materials, related companies, ongoing projects, and research.

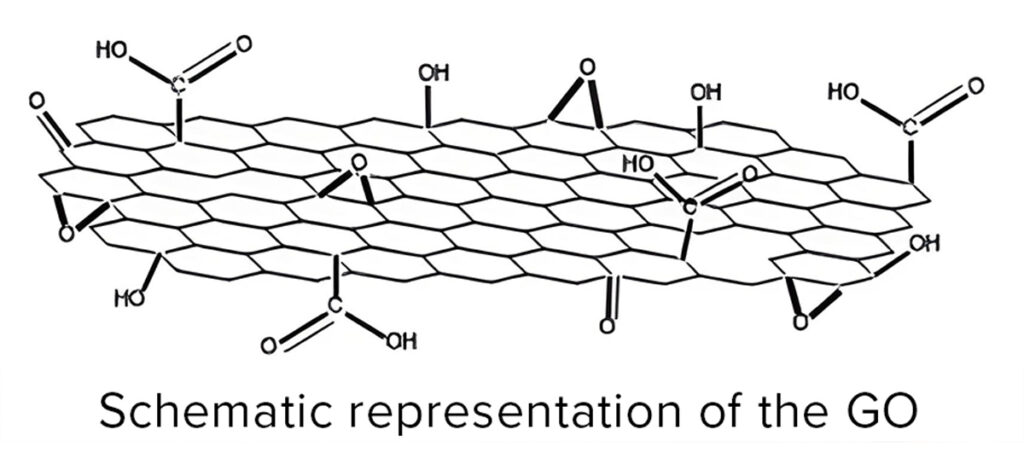

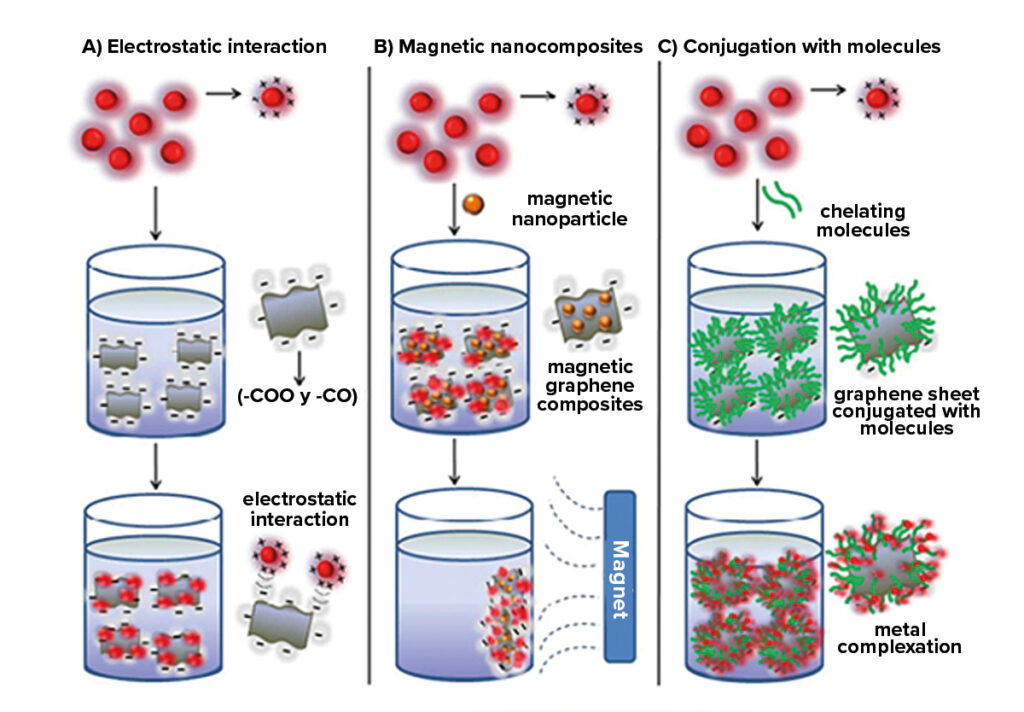

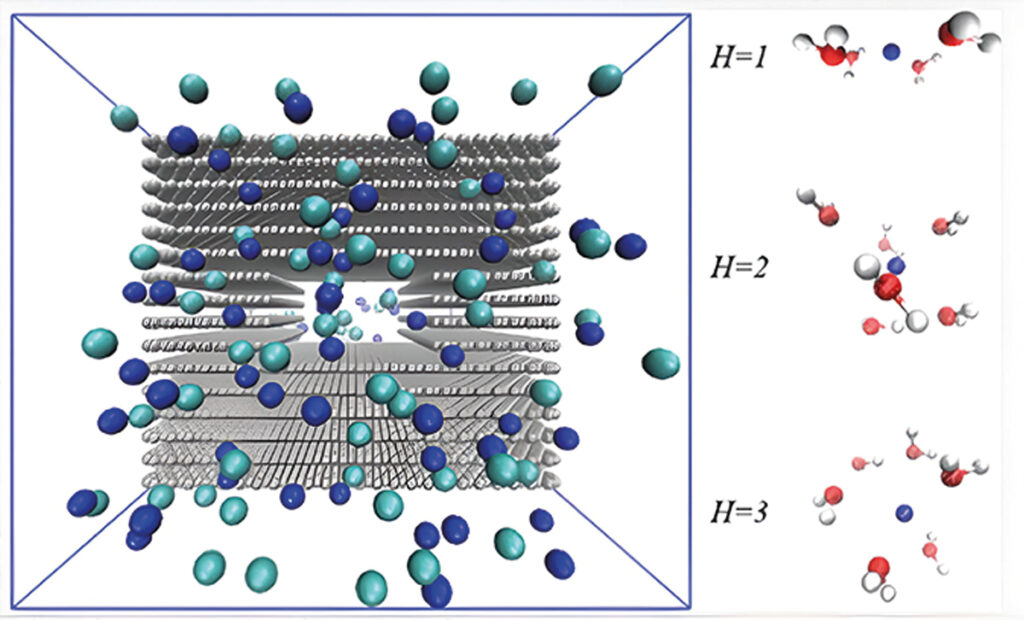

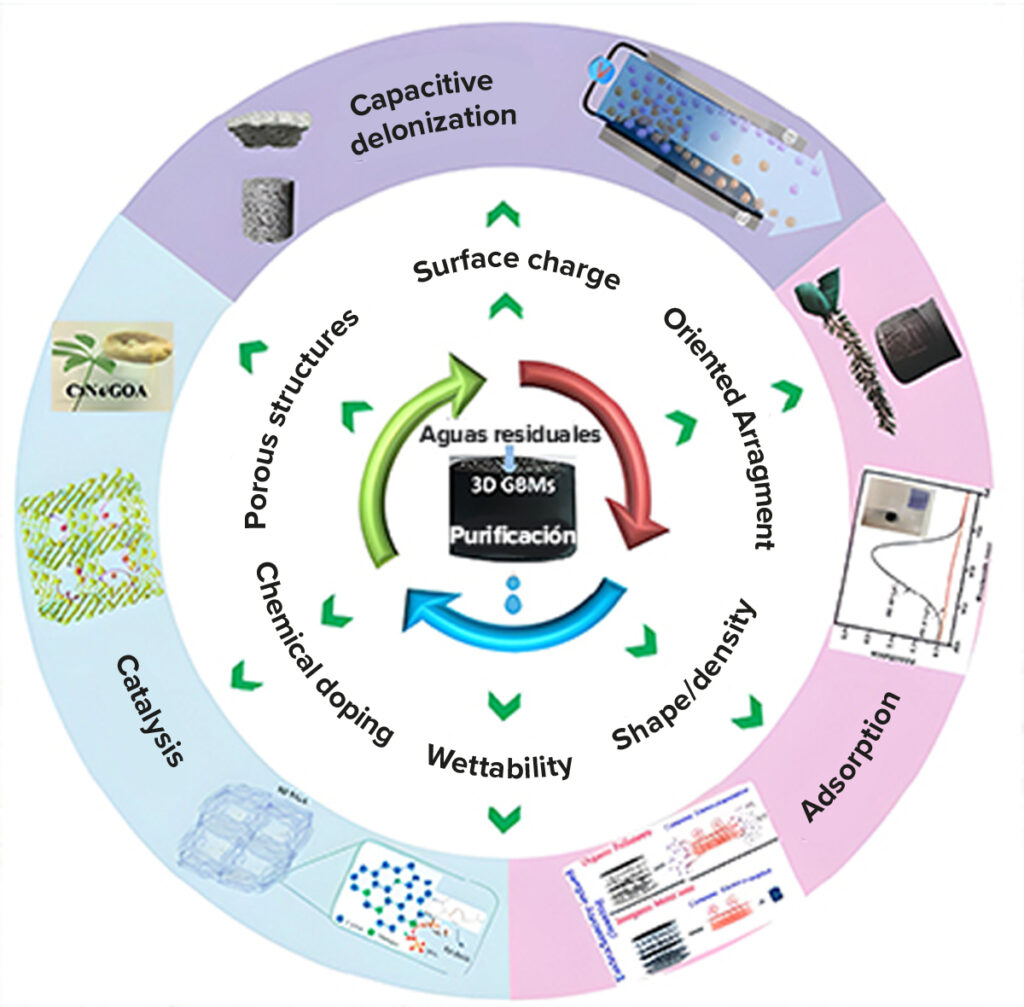

Graphene oxide (GO) is a carbon-based nanomaterial with sheet-like structures smaller than 100 nm or 0.1 microns in width and only one atom thick. It has hydroxyl (OH), epoxy (-O-), carboxyl (COOH), and carbonyl (C=O) functional groups on its surface that allow it to interact with cement C-S-H crystals, improving the hydration process. The properties of GO that make it attractive as a chemical modifier for cement include high tensile strength (130 GPa), large surface area (2630 m²/g), high thermal conductivity (5300 W/mK), and barrier properties. This interaction helps improve the properties of cement-based structures, such as concrete, resulting in the following:

- Reduced cement consumption in concrete structures while achieving similar mechanical properties, with compressive strength increased by 5% to 30%, tensile strength by 8% to 20%, elastic modulus by 4% to 12%, and abrasion resistance by 10% to 12%.

- Better quality and more durable concrete structures due to lower porosity, increasing impermeability by 12% to 60%, improving performance in aggressive environments.

- Enhanced thermal diffusivity of concrete, providing better thermal crack control, fire resistance, and de-icing capability for pavements.

- Improved workability, better appearance of structures, faster setting time, and easier mold release, as GO acts as a catalyst in the cement hydration reaction.

- Protection against microbiologically induced corrosion, as GO limits the conditions necessary for microbial attachment and reproduction.

Since 2018, Energeia-Graphenemex® has been exploring the benefits of graphene nanotechnology across various industrial sectors. As experts in the field, they recommend conducting validation tests, considering the multiple variables in the construction sector, especially those related to new cement compositions, to achieve optimal dosage results, always guided by trained personnel.

Authored by: EF/DHS

References

- M. Murali et al., Utilizing graphene oxide in cementitious composites: A systematic review. Case Studies in Construction Materials 17 (2022) e01359.

- Z. Pan, et al., Mechanical properties and microstructure of a graphene oxide–cement composite, Cem. Concr. Compos. vol. 58 (2015) 140–147, https://doi. org/10.1016/j.cemconcomp.2015.02.001

- E. Cuenca, L. D’Ambrosio, D. Lizunov, A. Tretjakov, O. Volobujeva, L. Ferrara, Mechanical properties and self-healing capacity of ultra high performance fibre reinforced concrete with alumina nano-fibres: tailoring ultra high durability concrete for aggressive exposure scenarios, Cem. Concr. Compos. vol. 118 (2021).

- N. Makul, Modern sustainable cement and concrete composites: review of current status, challenges and guidelines, Sustain. Mater. Technol. vol. 25 (2020); 5. L. Lu, P. Zhao, Z. Lu, A short discussion on how to effectively use graphene oxide to reinforce cementitious composites, Constr. Build. Mater. vol. 189 (2018) 33–41.

- Q. Wang, J. Wang, C.-x Lu, B.-w Liu, K. Zhang, C.-z Li, Influence of graphene oxide additions on the microstructure and mechanical strength of cement, N. Carbon Mater. vol. 30 (4) (2015) 349–356.

- https://canacem.org.mx/site/wp-content/uploads/2023/03/Hoja-de-Ruta-Mexico-FICEM.pdf.

- https://cdn.ymaws.com/www.thegraphenecouncil.org/resource/resmgr/case_studies/first_graphene__-_greening_c.pdf

- https://www.graphene-info.com