The impact of graphene

on the setting and strength of concrete

Setting accelerating additives for cement-based structures are usually used when it is necessary to reach the desired resistance in less time, either to maintain continuous production or when the product needs to be put into operation immediately. However, the large number of variables that interfere in this process makes it difficult to accurately anticipate the acceleration that can be obtained with each new additive; without forgetting the importance of controlling the exothermic reaction or heat release that occurs during the setting or curing of the cement to avoid the appearance of thermal cracks in the final product.

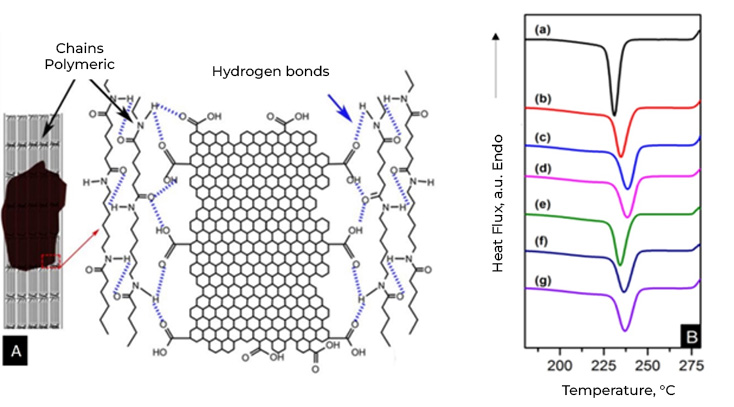

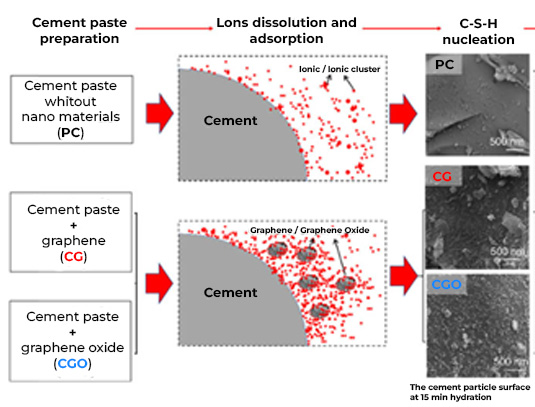

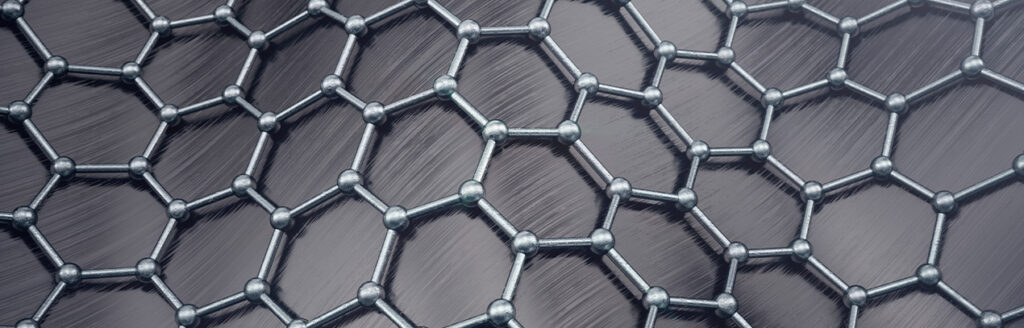

To understand part of the reactions that occur during the setting of cement, it is important to know a little about its composition, for example: around 75% is made up of tricalcium silicate and dicalcium silicate which, when reacting with water, form calcium hydroxide and silicate. hydrated calcium (C-S-H), the latter being a nanometric component and, at the same time, the most important element, since the setting, hardening, resistance and dimensional stability of the cement depend on it.

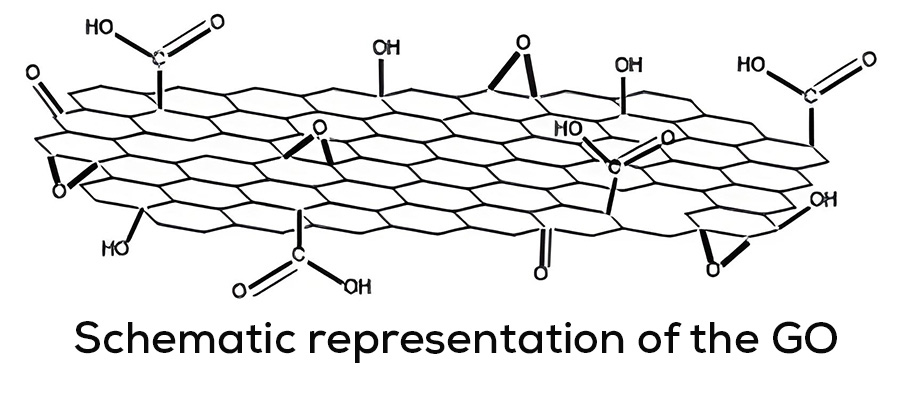

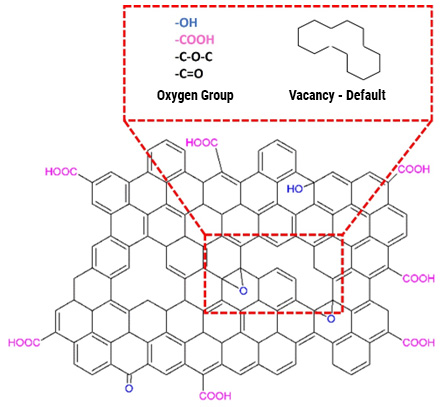

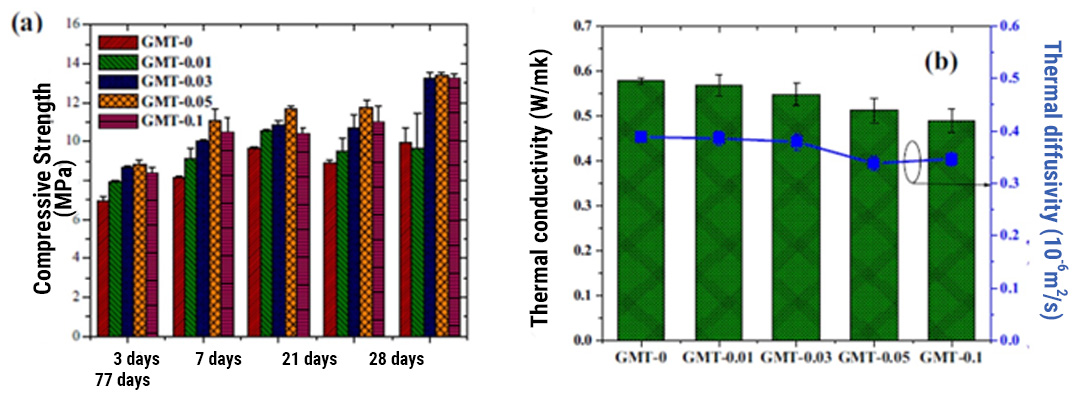

Previous articles have discussed the interesting interaction of C-S-H nanoparticles with graphene oxide (GO) nanoparticles, another nanometric structure composed of carbon atoms and oxygen groups that has captured the attention of the construction industry thanks to its benefits during the hydration of cement and the direct impact it has to improve its mechanical resistance and durability, but also its interesting role as a setting accelerator, mainly for lightened polymeric concretes.

“GO acts as a catalytic agent during the cement hydration reaction”

The presence of oxygenated groups on the surface of GO allows it to absorb water and cement molecules to stabilize, on one hand, the atoms in the C-S-H by providing oxygen sites for the silicate chains and on the other, to act as a reservoir of water and transport channels to improve the hydration of cement.

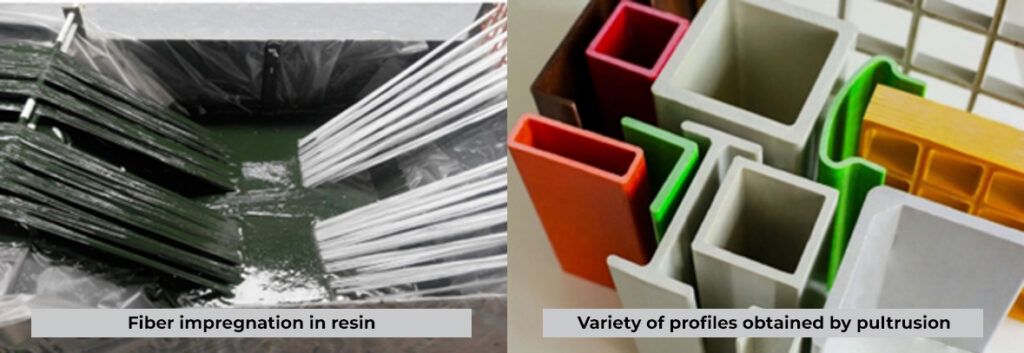

In addition, the excellent compatibility of GO with different types of resins made it the perfect candidate for reinforcing polymer-type concrete that, although it does not contain a significant phase of hydrated cement, Portland cement is often used as a filling material and, thus giving the GO a larger array to transfer its properties to.

Graphenergy Construcción® is a water-based multipurpose additive with a specialized formula based on Graphene Oxide that contributes to improve the microstructure of any cement-based product, offering the following benefits during the setting process:

Setting: Acceleration of setting time up to 30%.

Drying: Helps uniform drying with fewer marks or moisture spots.

Increased resistance during demoulding of precast products: Greater integrity of the structures, better definition of angles and a significant reduction of product fracture.

Resistance to thermal changes: the good thermal conductivity of its formulation promotes a more homogeneous heat distribution during the hydration of the cement and, therefore, contributes to reducing the appearance of thermal cracks and reduces product fractures in cold climates.

Good integration with other additives or components of concrete mixes. It favors the workability of the mixtures.

Drafting: EF/DHS

Sources

- Ultrahigh Performance Nanoengineered Graphene- Concrete Composites for Multifunctional Applications. Adv. Funct. Mater. 2018; 28: 1705183;

- The role of graphene/graphene oxide in cement hydration. Nanotechnology Reviews. 2021;10(1):768;

- Experimental study of the effects of graphene nanoplatelets on microstructure and compressive properties of concrete under chloride ion corrosion. Construction and Building Materials, 2022; 360, 129564;

- Effect Of On Graphene Oxide the Concrete Resistance to Chloride Ion Permeability. IOP Conf. Ser. 2018: Mater. Sci. Eng. 394 032020;

- Effects of graphene oxide on early-age hydration and electrical resistivity of Portland cement paste. Constr Build Mater. 2017; 136, 506;

- Recent progress on graphene oxide for next-generation concrete: Characterizations, applications and challenges. “J. Build. Eng. 2023; 69, 106192;

- Graphene nanoplatelet reinforced concrete for self-sensing structures – A lifecycle assessment perspective. J. Clean. Prod. 2019; 240, 118202;

- Graphene opens pathways to a carbon -neutral cement industry. Science Bulletin. 2021; 67;

- Reinforcing Effects of Graphene Oxide on Portland Cement Paste. J. Mater. Civ. Eng. 2014; A4014010-1;

- A review on the properties, reinforcing effects, and commercialization of nanomaterials for cement-based materials. Nanotechnology Reviews, 2020; 9: 303–322, 10;

- Chloride permeability of reinforced concrete located in a submerged marine environment. Construction Engineering Magazine. 2007; 22: 1, 15;

- Penetrability of concrete to water and aggressive ions as a determining factor of its durability. Construction Materials, 1973; 23: 150;

- Electrical resistivity as a control parameter of concrete and its durability. ALCONPAT Magazine, 2011; 1 (2), 90,

- Portland cement blended with nanoparticles. Dyna, 2007; 74:152, 277;

- Improvement in concrete resistance against water and chloride ingress by adding graphene nanoplatelet. Cem concres, 2016; 83:114;

- Catalytic behavior of graphene oxide for cement hydration process. Journal of Physics and Chemistry of Solids, 2016; 89: 128.

- Review on Graphene oxide composites. Int. J nanomater nanostructures. 2016; 24.