Graphene and Bioplastics:

Innovation for Enhanced Sustainability

Awareness of environmental protection and the commitment to meeting the United Nations’ 2030 Sustainable Development Goals (SDGs) have fueled the growth of the bioplastic industry. This sector is striving to take the lead in the race against synthetic products, many of which, while non-toxic and recyclable, lack biodegradability.

“Currently, only 1% of all plastic produced is bioplastic.”

What Are Bioplastics?

Bioplastics are materials derived from natural and chemical sources, obtained from renewable resources or petroleum-based derivatives. As a result, they offer major advantages, including full biodegradability, high recyclability, and a minimal carbon footprint. Additionally, bioplastics exhibit excellent optical, mechanical, antioxidant, and antimicrobial properties. However, like most materials, bioplastics also have limitations, the two most notable being low tensile strength and moisture resistance.

Despite these challenges, and given the goal of minimizing carbon footprints and reducing the use of synthetic or single-use polymers, the bioplastic industry has been evolving to overcome its limitations. This has been achieved through the incorporation of reinforcing agents such as fillers, compatibilizers, plasticizers, and even nanotechnology through the use of nanoparticles.

The most well-known bioplastics include polylactic acid (PLA), polyhydroxybutyrate (PHB), cellulose derivatives, starch, and chitosan. Among them, PLA has gained significant traction as a biodegradable thermoplastic polymer approved by the FDA. In recent years, it has emerged as a viable alternative to replace non-biodegradable fossil-based polymers traditionally used in the food, medical, agricultural, textile, and automotive industries. PLA exhibits characteristics like some petroleum-derived plastics. As a result, numerous PLA-based products are already available in the market, including blow-molded bottles, injection-molded cups, spoons, and forks, thermoformed trays and cups, paper coatings, textile fibers, and even medical supplies.

“Over 160 tons of PLA packaging are produced annually, accounting for approximately 13% of all bioplastics, making it the second most used in the sector after starch.”

PLA is produced from lactic acid through the fermentation of renewable resources such as rice, wheat, corn, sugarcane, potatoes, and beets. Due to its nature, PLA shares similar mechanical and barrier limitations with other biomaterials. As a result, various strategies have been developed to enhance its properties. For example, to improve its crystallinity and biodegradability, PLA is combined with polymers such as polyethylene glycol, ethylene vinyl alcohol, or poly(butylene adipate-co-terephthalate). To maintain its compostability, it is blended with other starch-based biopolymers such as corn, cassava, and beet starch. Finally, to improve impermeability, tensile strength, and thermal stability, graphene has emerged as a highly promising material.

“Other nanoparticles used in the bioplastic industry include silver, magnesium oxide, zinc oxide, titanium dioxide, hydroxyapatite, silica, alumina, magnetite, zirconium oxide, calcium carbonate, and recently, graphene.”

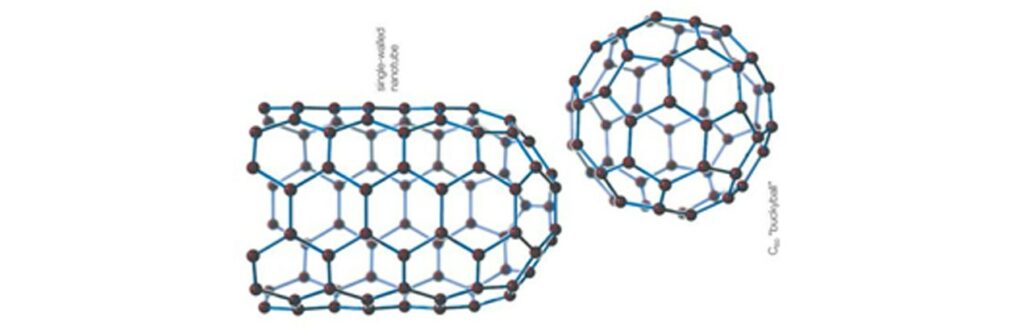

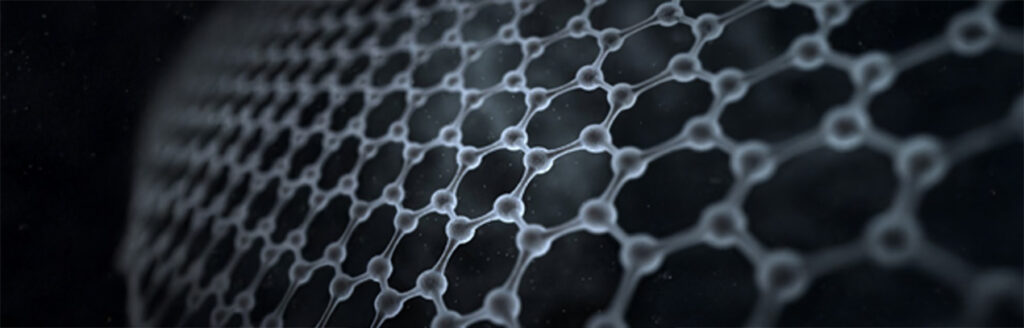

¿ What Is Graphene?

Graphene is a nanoscale structure generally extracted from graphite, a mineral composed solely of carbon. Unlike graphite, however, graphene consists of one or a few layers of tightly interconnected carbon atoms. It can be combined with numerous compounds to enhance its mechanical, thermal, electrical, barrier, and antimicrobial properties.

The benefits of graphene in biopolymers such as PLA are extensive. For example, studies have incorporated small amounts of graphene into compostable PLA films with thermoplastic cassava starch for food and agricultural applications. Remarkably, using just 0.1% graphene has resulted in:

- ~75% improvement in elongation resistance

- ~500% increase in film toughness

- 100% enhancement in elasticity modulus

- 35-50% reduction in oxygen permeability

Regarding mechanical improvements, studies conclude that in graphene-reinforced polymers subjected to tensile stress, surface fractures propagate freely unless they encounter a graphene sheet. Since graphene is a rigid material, the fracture is forced to find an alternate path, increasing deformation energy and ultimately resulting in high elongation-to-break values.

“Low concentrations of graphene are sufficient to create a crack-bridging mechanism during tensile stress. However, high concentrations can lead to nanoparticle agglomeration, causing the opposite effect.”

Increased impermeability to oxygen and moisture is another key advantage, attributed to the tortuous path created by graphene layers within the polymer. This structure hinders the penetration and movement of molecules. This phenomenon is closely linked to good graphene-polymer compatibility and dispersion, which prevents material aggregation. To improve compatibility, graphene can be chemically modified with oxygen-containing groups, leading to its most well-known variant: graphene oxide (GO). The presence of oxygen and hydrogen molecules in GO allows for further functionalization with other nanoparticles (e.g., cellulose or zinc oxide nanocrystals) or compounds (e.g., amine or amide groups), modifying its behavior based on the desired objective.

For example, a 2023 study published in Polymer Testing evaluated PLA barrier properties using GO functionalized with two types of alkylamines (decylamine (DA) and octadecylamine (ODA)) to enhance its food packaging performance. The results reported a 30% reduction in oxygen permeability with just 0.7% functionalized GO and a 50% reduction in water vapor permeability using 0.2% GO, significantly extending shelf life. If PLA can further improve its properties, it has the potential to replace polystyrene and PET—two of the most widely used materials in the packaging industry.

Graphene’s Antimicrobial Potential

Another crucial advantage of graphene—not only in PLA but in other materials—is its well-documented antimicrobial properties, which do not necessarily involve a biocidal effect. One of graphene’s mechanisms is preventing microorganism adhesion to surfaces through various pathways, regardless of their nature.

Specific research on PLA with graphene also supports this claim. Studies indicate that incorporating 1% GO in PLA films reduces film porosity, decreases oxygen permeability, and demonstrates significant antimicrobial activity against Staphylococcus aureus and Escherichia coli. These properties further enhance its potential for food packaging and preservation.

Conclusion

This article used PLA as a model to illustrate the benefits graphene can offer to the bioplastic industry. However, other biomaterials such as chitosan, cellulose, and starch can also be significantly improved with graphene.

In general, research shows that graphene has the potential to enhance multiple properties of materials. However, achieving this requires:

- Selecting the right type of graphene

- Determining its optimal concentration

- Assessing the need for chemical modifications to optimize performance for different applications

Ultimately, striking a favorable balance between mechanical, barrier, and optical properties is essential. By leveraging graphene’s unique characteristics, the bioplastic industry can move closer to sustainable, high-performance materials with reduced environmental impact.

Written by: EF/DHS

References:

- Remilson Cruz, et al., Development of biodegradable nanocomposites based on PLA and functionalized graphene oxide. Polymer Testing 124 (2023) 108066

- Mulla, et al., Poly Lactic Acid (PLA) Nanocomposites: Effect of Inorganic Nanoparticles Reinforcement on Its Performance and Food Packaging Applications. Molecules 2021, 26, 1967

- Saranya Ramesh Kumar et. al., Bio-based and biodegradable polymers – State-of-the art, challenges and emerging trends. Current Opinion in Green and Sustainable Chemistry 2020, 21:75

- De Carvalho, A.P.A.; Conte Junior, C.A. Green strategies for active food packagings: A systematic review on active properties of graphene-b Trends Food Sci Technol, 103, 2020, 130

- Anibal Bher et. al., Toughening of Poly(lactic acid) and Thermoplastic Cassava Starch Reactive Blends Using Graphene Nanoplatelets. Polymers 2018, 10, 95

- Yasir Ali Arfat et. al., Polylactide/graphene oxide nanosheets/clove essential oil composite films for potential food packaging applications. Int. J. Biol. Macromol, 107, 2018, 194

- Valapa, R.B.; et. al., Effect of graphene content on the properties of poly(lactic acid) nanocomposites. RSC Adv. 2015, 5, 28410

- Ahmadi-Moghadam, et. al., Effect of functionalization of graphene nanoplatelets on the mechanical response of graphene/epoxy composites. Mater. Des. 2015, 66, 142

- Seshadri, M.; Saigal, S. Crack bridging in polymer nanocomposites. J. Eng. Mech. 2007, 133, 911